ARCHITECTURE OF RAMMED EARTH

Sustainable Design Synthesis

Supported by 2019 GuSH Research Grant

Guides: Prof. Dana Cupkova | Prof. Steve Lee

Co-Advisor: Lola Ben-Alon

Rammed earth construction is an Environmentally benign alternative to current

construction materials. It utilizes locally sourced materials, requires minimal processing,

and is a healthy, non-toxic material providing greater indoor air quality.

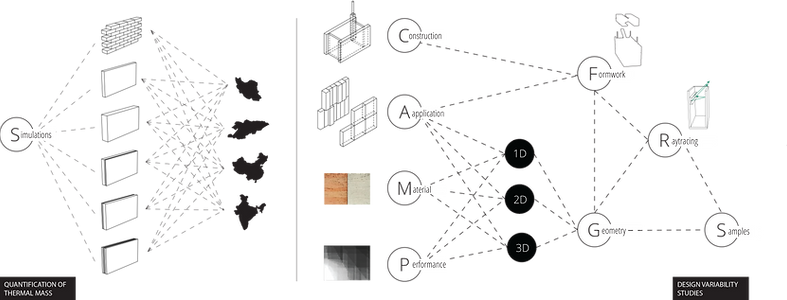

This study explores the effectiveness of rammed earth as wall panels in hot and arid

climates. It aims at identifying digital tools and processes to introduce greater design

variability in Rammed Earth.

Changing the narrative around rammed earth

The study evaluates performance criteria and geometrical semantics that are then translated to physical prototypes using digital fabrication

technology. The project introduces an innovative formwork design to construct these geometries.

The current formwork design and construction techniques have been the defining factors in the familiar monolithic rammed earth wall design.

There are two critical members that contribute to this design vocabulary. Firstly, the formwork needs to be rigid, stable and able to withstand the construction forces. And Secondly, to achieve a dense and well-compacted wall, the rammer has to reach each section of the rammed earth module.

To address this issue, a new formwork module was developed which can be fitted within the conventional formwork to develop new geometries.

The formwork is made of timber or plywood pieces. The digital model is sliced into manageable sections. Each section is then milled into the internally placed module. This increases the reach of the rammer, providing the ability to design and construct complex geometries that were otherwise not possible with conventional formwork.

To map the reachability of the rammer based on the newly devised construction technology, a computational model was developed to conduct ray tracing simulation. The vector reachability is indicative of the ability to achieve even compression by direct reachability of rammer to each surface node.

Restackable formwork was designed

to achieve finite geometrical

transformations using a limited

number of modules.